OPE distributors, how to react “Power Cuts”, “Lack Containers”, “Raw material Rise”?

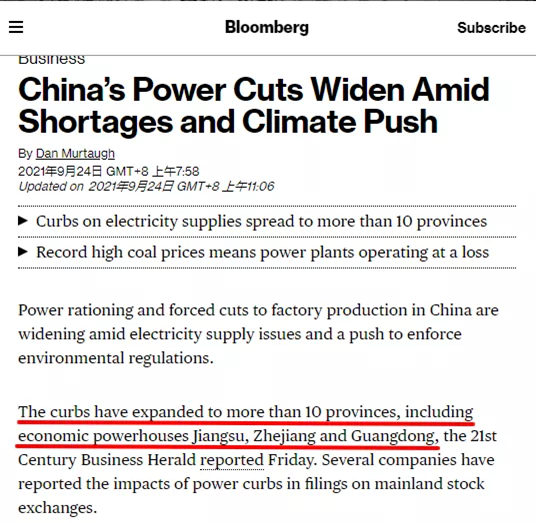

In 2021,Power Cuts policy,Raw materials in the OPE industry and sea freight increased surprisingly. It brought headache task for the OPE distributor owners.

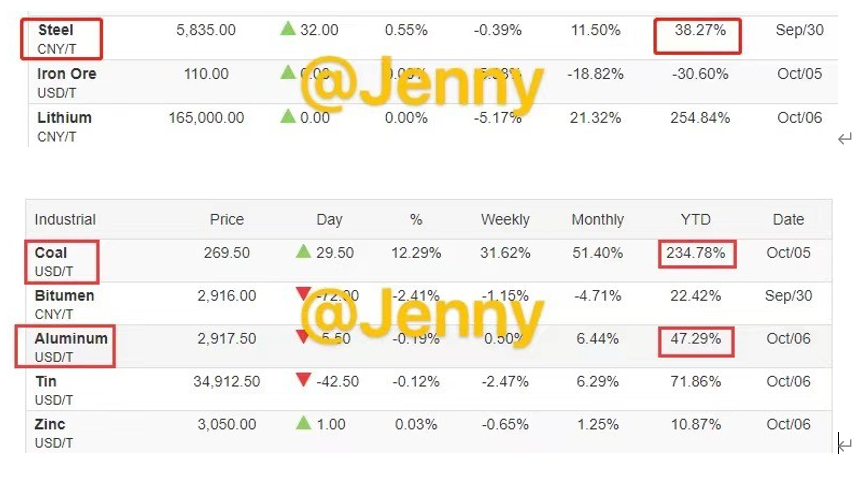

The raw materials Steel, Aluminum, Copper, Filter Paper, Rubber increased about 30%-50% from November 2020 to October 2021. Very crazily.

For this reason, the factory’s cost has increased accordingly.

The growth of raw materials is not only happened in China, but also for all global manufacturers.

Here attached the screenshot from Jan 1st- Oct 7th 2021 below:

Because the “Power Cuts” policy of the Chinese government, most of the factories have been adjusted to “work for 7 days and stop 7 days”, and the production capacity is only half of that under such circumstances.

How to solve these tough issues? Here are the professional suggestions:

a) The reliable OPE parts suppliers always have both the plan A and Plan B. If the factory has the good plan, the Power Cuts policy can be solved.

b)Raw materials rise has almost no big effect on distributors if the supplier would like to keep the same quality as before and share some cost and pursue long-term cooperation

c)Container shortage are better this month on October, the most serious is last 3 months, but LCL is better than FCL.

I have 10 years of cooperation experience with OPE parts globally renowned distributors.

More than 200 distributors from 52 countries have gained 50% increase each year through our support.

When I treat others, I always take the friendship in the first place, business is the second.